Category

- AB Suppressors

- ACE Barrels

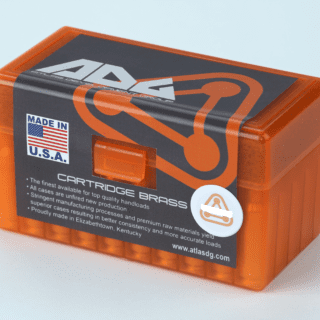

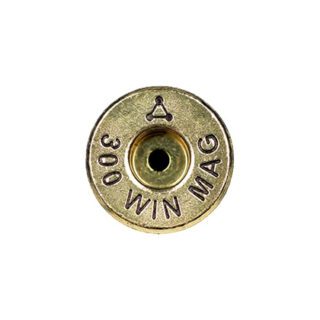

- ADG BRASS

- Aero Precision

- AG Composites

- Arca – Picatinny Rails

- Atlas bipods & accessories

- Banish Suppressors

- Bargain Cave

- Benchmark Barrels

- Bergara

- Berger Bullets

- Bipods

- Bolt Knobs

- Carbon Fiber Barrels

- Cerakote Services

- Christensen Arms Actions & Accessories

- Custom Rifles

- Dead Air Silencers

- Defiance Actions

- Gun Screws

- Gunsmith Services

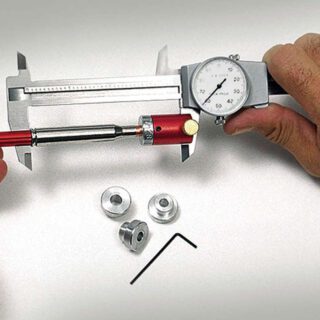

- Gunsmith Tools

- Gunwerks

- H-S Precision

- Hawkins Precision

- Hells Canyon Armory

- Hornady

- Kelbly Actions

- Kinport Peak Rifles Barrel Services

- KRG

- Lapua

- Leupold Optics

- Manners Stocks

- McMillan Stocks

- MDT Chassis

- Meraki Machine

- Mesa Precision Arms

- Mountain Tactical

- Muzzle Brakes

- Nightforce Optics

- Norma Brass

- Optics

- Proof Research

- Pure Precision

- Redding Reloading

- Remington Actions & Accessories

- Ruger

- Savage actions & accessories

- Suppressors

- Thunder Beast Suppressors

- Tikka Actions & Accessories

- Tricer

- TriggerTech Triggers

- Vortex Optics

- Weatherby

- Winchester

- XLR Industries

Products

- AB Suppressors

- ACE Barrels

- ADG BRASS

- Aero Precision

- AG Composites

- Arca - Picatinny Rails

- Atlas bipods & accessories

- Banish Suppressors

- Bargain Cave

- Benchmark Barrels

- Bergara

- Berger Bullets

- Bipods

- Bolt Knobs

- Carbon Fiber Barrels

- Cerakote Services

- Christensen Arms Actions & Accessories

- Custom Rifles

- Dead Air Silencers

- Defiance Actions

- Gun Screws

- Gunsmith Services

- Gunsmith Tools

- Gunwerks

- H-S Precision

- Hawkins Precision

- Hells Canyon Armory

- Hornady

- Kelbly Actions

- Kinport Peak Rifles Barrel Services

- KRG

- Lapua

- Leupold Optics

- Manners Stocks

- McMillan Stocks

- MDT Chassis

- Meraki Machine

- Mesa Precision Arms

- Mountain Tactical

- Muzzle Brakes

- Nightforce Optics

- Norma Brass

- Optics

- Proof Research

- Pure Precision

- Redding Reloading

- Remington Actions & Accessories

- Ruger

- Savage actions & accessories

- Suppressors

- Thunder Beast Suppressors

- Tikka Actions & Accessories

- Tricer

- TriggerTech Triggers

- Vortex Optics

- Weatherby

- Winchester

- XLR Industries

Top rated products

-

Triggertech Primary Trigger

$174.99

Triggertech Primary Trigger

$174.99

-

TriggerTech Diamond Flat Straight

$334.99

TriggerTech Diamond Flat Straight

$334.99

-

TriggerTech Diamond Curved

$334.99

TriggerTech Diamond Curved

$334.99

-

BT46-LW17 PSR Atlas Bipod

$354.95

BT46-LW17 PSR Atlas Bipod

$354.95

-

BT47-LW17 PSR Atlas Bipod

$374.95

BT47-LW17 PSR Atlas Bipod

$374.95

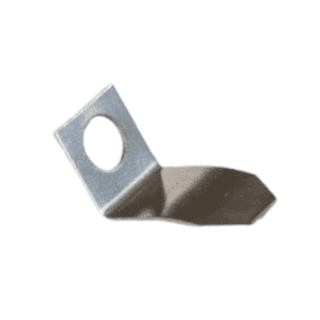

Remington 700 Recoil Lugs

Remington 700 Recoil Lugs offered in a variety of profiles and thicknesses.

Remington 700 Pure-Precision Profile Pinned 1.065″ bore .250″ Thick

Precision made Remington recoil lugs that are the easier to install Pure Precision profile. Our profile lugs are less wide and less tall so that they require less stock inletting to achieve the same goal as other profile recoil lugs. Our recoil lugs are manufactured from start to finish in house in Idaho out of 416 HT stainless steel. This specific stainless material we utilize is heat treated prior to machining and is between 28-32 Rockwell hardness. Each recoil lug is surface ground to within .0002″ parallelism or better to prevent any uneven pressures exerted on the (hopefully) trued receiver and barrel tenon shoulder. Our surface grinding process includes the heavy use of flood coolant to prevent any heat warping and results in a near mirror finish for each lug face. This lug has an indexing through hole just below the bore to allow the installer to pin it to the receiver. This prevents the lug from ever turning from its proper clocked position. (Hardened dowel pin included)

Height: 1.700″ +/-.005″

Width: 1.305″

Thickness: .250″

Bore Diameter: 1.062″-1.065″

Proudly made in the U.S.A.

Remington 700 Tubb Profile Pinned 1.065″ Bore .250″ Thick

Precision made Remington recoil lugs that match the Tubb famous profile. Our recoil lugs are manufactured from start to finish in house in Idaho out of 416 HT stainless steel. This specific stainless material we utilize is heat treated prior to machining and is between 28-32 Rockwell hardness. Each recoil lug is surface ground to within .0002″ parallelism or better to prevent any uneven pressures exerted on the (hopefully) trued receiver and barrel tenon shoulder. Our surface grinding process includes the heavy use of flood coolant to prevent any heat warping and results in a near mirror finish for each lug face. This lug has an indexing through hole just below the bore to allow the installer to pin it to the receiver. This prevents the lug from ever turning from it’s proper clocked position. (Hardened dowel pin included)

Height: 1.840″ +/- .005″

Width: 1.340″

Thickness: .250″

Bore Diameter: 1.062″-1.065″

Proudly made in the U.S.A.

For a recoil lug that requires less stock modification, see our Pure-Precision profile recoil lugs.

Pure Precision (pure-precision.com)

J&A Outdoors – Firearm Solutions – Shooting Products (jaoutdoors.com)

| Profile: | Remington Pure-Precision Profile Pinned 1.065" bore .250" Thick, Remington Tubb Profile Pinned 1.065" Bore .250" Thick, Factory Remington Unpinned 1.065" Bore .250" Thick, Factory Remington Unpinned 1.065" Bore .188" Thick |

|---|

Related products

-

Remington 700 Bolt Stop

$29.99Original price was: $29.99.$25.00Current price is: $25.00.Add to cartThis fits Remington 700’s – right or left hand.

Long Action

Short Action

This is a custom cut extended length bolt stop that allows your bolt to reach farther back for Wyatt extended magazines – OR – run this on a factory Remington 700 without issues!

-

Remington 700 & Christensen Stripped Actions

$275.00 – $375.00Price range: $275.00 through $375.00Select options This product has multiple variants. The options may be chosen on the product pageRemington 700 & Christensen Stripped Actions These Remington 700 & Christensen stripped actions are new take off’s. Please note, that in some rare instances there may be minor marks from barrel removal. Remington & Christensen bolt assemblies can be found here: https://jaoutdoors.com/product/remington-700-bolts/ J&A Outdoors – Firearm Solutions – Shooting Products (jaoutdoors.com) ***MUST SHIP …

Email Newsletter

Best offers

100% Safe

Secure Shopping

Quick Customer Support

Tuesday-Friday